| Introduction |

| Physics of HTS |

| HTS materials |

| HTS leads |

| Resistive leads |

| Other activities |

| Contracts |

| Publications |

HTS materials for LHC current leads

|

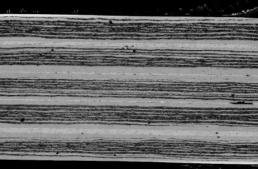

As part of an intensive R&D program which started in early 1995 and ended in 2002, a full range of HTS materials were studied and tested at CERN. The scope of this work was to verify their current capability at temperatures of up to 77 K, their suitability for reproducible low resistance and high current joints, their behavior in case of resistive transition and their thermal performance. These materials, tested either in the form of samples or integrated in prototype current leads, were: Bi-2223 tape with various percentage of Au in the Ag matrix, DIP coated Bi-2212, Melt Cast Processed Bi-2212, Accordion Folding Method Bi-2223, Melt Textured Y-123, Ceramo Crystal Growth Y-123 and Laser Floating Zone Bi-2212. In view of its good thermal and electrical performance and established quality control procedures associated with industrial scale production, the Bi-2223 tape was identified as being the most suitable material for application to the LHC HTS current leads. Bi-2223 tape and Bi-2223 stacksThirty-one kilometers of Bi-2223 tape were purchased from two manufactures (AMSC and EAS). The tape was specified to have superconducting filaments- (Bi,Pb)2Sr2Ca2Cu3OX, X » 10- embedded in a silver alloy matrix doped with gold. The percentage of gold in the matrix is in the range from 4 to 5.3 weight percentage. The tape, 4 mm wide and 0.2 mm thick, was delivered in spools having a minimum length of 100 metres. The measured average critical current of the spools, at 77 K and in self-field, is about 100 A. The Bi-2223 tape is integrated in the current leads in form of stacks. A number of five to nine tapes are vacuum soldered together to form a comparatively rugged conductor transporting, at 77 K and in self-field, a current between 350 A and 600 A. This activity of vacuum soldering of the tapes into stacks is performed at CERN: the tape is inspected, cut to the required length, assembled into appropriate moulds and vacuum soldered in the CERN vacuum soldering facilities. About 10000 HTS stacks are being manufactured at CERN for integration in the LHC current leads. As part of the quality control program, all stacks are characterized in liquid nitrogen and in self-field. The n-exponent value of the stacks, calculated as the slope of the logarithmic plot of the voltage versus current in the range from 0.1 mV/cm to 2 mV/cm, is about 20. For all stacks, the critical current is measured for electric fields of 0.1 mV/cm, 1 mV/cm and 2.5 mV/cm. For full traceability, the spool and the stack characteristics and their characterization curves are stored in a database, together with the information related to the current lead and to the LHC magnet circuit powered by the leads. Some stacks, representative of each different type integrated in the current leads, underwent a full characterization at 77 K and 65 K in magnetic fields, parallel and perpendicular to stacks, of up to 0.5 T. Short samples of Bi-2223 tape underwent tests of irradiation by fast neutrons both at room and liquid nitrogen temperatures. It was found that integrated doses of up to 5.10-15 cm-2 , equivalent to about 500 kGy, do not give rise to significant degradation of the critical current of the tape. To prevent "bubbling" of the stacks, which will be exposed during the LHC operation to liquid helium and cold helium gas, a coating procedure has been proposed and validated by CERN. It consists in the vacuum impregnation of the HTS stacks with a thin layer of the polymer poly-para-xylene (ParyleneÒ). The vacuum impregnation takes place at room temperature on the stacks already assembled on the supporting structure that is part of the current lead assembly.

|

|

| last changed: 2005-11-23 | webmaster: Amalia Ballarino |