|

The powering of

the LHC close orbit correctors will be made via 1504 current leads rated for a

maximum current of 60 A. Additional 520 current leads are needed for the

powering of the corrector magnets operating at currents of up to 120 A. At CERN, two different designs

were developed for these leads:

· a

conduction-cooled design, for all the 60 A leads and for part -324 in total- of the

120 A leads;

· a

gas-cooled design for the remaining 120 A current leads.

Conduction-cooled current leads

The

conduction-cooled current leads are integrated in the main vacuum insulation

of the LHC Short Straight Section (SSS) cryostats. They transport the

current from room temperature to the 1.9 K liquid helium bath. In view of

their important number and of the strong space constraints imposed by the

cryostat configuration, they are assembled in a group of four on a common

stainless steel flange. They are pre-shaped as requested by the integration

requirements, which require that these leads are the last components to be

integrated into the already densely packed LHC cryostats.

An hybrid

conductor, electrical insulated via a multilayer Kapton® tube, is first

inserted in a thin stainless steel tube and then pre-shaped with a tooling,

specially developed at CERN. The four tubes are finally welded to the warm

and cold stainless steel flanges. The hybrid conductor is a red brass rod that

is copper plated along the entire length with two different copper

thickness (thinner in the lower part). This hybrid conductor was chosen in order to minimize the heat

load into the helium bath while assuring good stability in case of thermal

run-away. The conductors of each assembly are thermalized against two heat

sinks that are fixed to two cryogenic lines carrying gas

at 50 K-75 K and at 5 K-20 K respectively. The heat sinking at intermediate

temperatures is made in order to minimize the heat losses into the liquid

helium bath.

The design of

these leads is extremely compact. It has the advantage, when compared to

conventional self-cooled leads, of not requiring warm valves and pipes for

the control and recovery of the helium flow. It avoids the use of cold

vacuum-tight ceramic feedthroughs. In addition, thanks to the material choice and to the good

design of the heat sinks, the leads have good thermal performance. The calculated

losses into the helium bath of the a 60 A current leads are < 90 mW

at 15 A, which is the average current estimated for these corrector

magnets, and 170 mW at maximum current. For comparison, a conventional

conduction-cooled current lead operating at 60 A would conduct about 2.5 W into the bath.

The predicted thermal and electrical performance of the 60 A current leads have been

confirmed by precise measurements performed on series components integrated in a

ad-hoc cryostat built in the

University of Southampton.

The series

production on the 60 A and 120 A conduction-cooled current leads is being

manufactured on the basis of a CERN "build-to-print" design respectively in

Mark&Wedell, Copenhagen, and in CECOM, Rome.

Gas-cooled current leads

The

gas-cooled current leads are integrated in cryostats, located in the

insertion regions of the LHC machine, which house also the HTS current

leads. They transport the current from room temperature to the 4.5 K liquid

helium bath. The design is very compact. Depending on the requirements of

the powering, the leads are assembled in groups of four or eight on a common

supporting flange. The novelty of this design with respect to conventional

self-cooled current leads consists in extracting the heat from the leads of

the same assembly via common heat exchangers, cooled by the gas produced by

the thermal conduction of the leads themselves at 4.5 K. This solution has

two important advantages: the reduction in the number of valves

needed for the cooling of the leads from one per lead to one per lead

assembly, with significant economical savings in particular in view of the

important number of leads, and the compactness of the design, which is made

possible also by the simplification of the cooling scheme. The thermal

performance of these leads is comparable to the one of conventional

self-cooled current leads optimized for the same current rating.

|

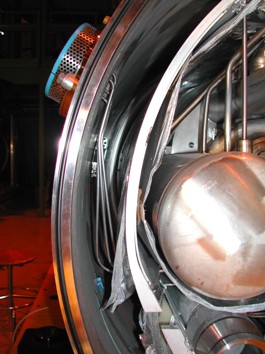

60 A Current Lead Assembly

60 A Current Lead Assembly in LHC cryostat

120 A current lead assembly in SSS cryostat

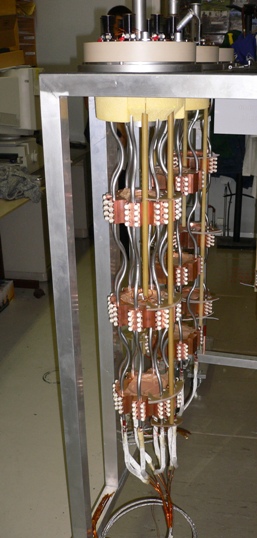

Cryogenic test, in ENEA, of 120 A

gas-cooled current lead

assembly (8 leads)

120 A gas-cooled current lead assembly |