Table of contents

1 Introduction

1.1 Team members

2 Physics of HTS

2.1 Applications

3 HTS materials

4 HTS leads

5 Resistive leads

6 Other activities

7 Contracts

8 Publications

Introduction

|

The powering of the LHC

superconducting magnets will be made via 3250 current leads transporting in total

about 3 MA of current into the “cold-mass” of the LHC machine. They

will be installed in the LHC tunnel, where they will provide the electrical link between the room temperature

power cables and

the cold bus-bars, bringing the current from/to the cryo-magnets.

Among the LHC current leads, 1030 components incorporate a section with HTS

(High Temperature Superconducting) material. Optimized conventional

self-cooled current leads conduct into the liquid helium about 1.1 W/kA. For

the LHC HTS current leads, the use of HTS material allows a reduction of

heat load into the liquid helium by a factor of 10 if compared to

conventional self-cooled leads. The reduction in total cooling power is

about a factor of 3.

Following an intensive R&D

program, which started at CERN in early 1995, devoted to the test of high

current HTS elements,

the Bi-2223 tape with a silver-gold

alloy matrix has been

selected as the most suitable material for the LHC current lead application. The HTS current leads for the LHC machine represent the first application of HTS

material in a large scale accelerator system.

The HTS

current leads are used for circuits operating at ultimate currents comprised

in the range 600

A to13000 A. They are designed as three different types optimized for operating respectively at 600 A,

6000 A and 13000 A. They power the LHC main dipole and quadrupole

magnets, the dipole and quadrupole magnets in the matching sections and

dispersion suppressors and some of the

corrector magnets.

The remaining leads, which are resistive, feed the 60 A and 120 A

electrical circuits of the corrector magnets. They are 2024 in total and

they are designed as three different series: a series of 60 A and 120 A

conduction-cooled leads and a series of 120 A gas-cooled leads. In spite of their important number, these resistive leads transport only about 5 % of

the total current powering the LHC magnet circuits. They are of a special

design which was developed to satisfy the LHC requirements of

flexibility and compactness while having good electrical and thermal performance.

The design of all these LHC leads was made and validated at CERN with the construction and test of

prototype units. Key-issues of the design are the optimization of the

thermal and electrical performance, the compactness and sturdiness of

the components, which are conceived to guarantee continuous operation of the

magnet systems during the LHC lifetime. The final series are being

manufactured in industry and external laboratories on the basis of CERN “build-to-print” designs.

Mandate of

the AT-MEL-CF section

-

Optimization and design of all the current leads, both resistive and

superconducting, powering the LHC magnets;

-

Specification,

procurement, assembly and test of the HTS

material to be integrated in the superconducting current leads;

-

Specification

and procurement of all the current leads powering the LHC superconducting

magnets;

-

Qualification

and test in nominal operating conditions of all

superconducting current leads prior to installation in the LHC cryostats;

-

Specification

and procurement of the electrical ancillaries for the current leads to be installed

and operated in the LHC tunnel.

|

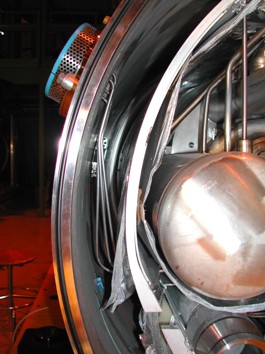

HTS-LTS Electrical joint

13000 A and 600 A HTS current leads

Top view of 600 A HTS current lead assembly |

Team members

| Name |

Main field of activity |

| Amalia Ballarino |

Section Leader |

| Pascal Chambouvet |

HTS materials, tests&assemblies, LHC on-call support |

| Philippe Denis |

Electro-mechanics for superconducting devices |

| Alain Gharib |

Cryogenic tests, electronics, LHC on-call support |

| Alain Jacob |

Electro-mechanics for superconducting devices |

| Stephen March |

PhD student-University of Southampton |

| Tiziana Miani |

ASP student-Politecnico of Torino (HTS leads-ITER) |

| Birgit Weckenmann |

Associated-GSI Darmstadt (HTS leads-FAIR) |

|

Physics of HTS

Since the discovery of High Temperature Superconductivity in

lanthanum copper oxides, discovery marked by the award

of the Nobel prize to Bednorz and Muller in 1987, no generally accepted

microscopic theory for the mechanism responsible for the superconductivity in

High Temperature Superconductors (HTS) has been formulated. After the lanthanum-barium-copper

oxide superconductors (La2-xBaxCuO4), having a

critical temperature of about 30 K,

other materials belonging to the same cuprate family were found to be superconducting

at even higher temperatures: the yttrium-barium-copper-oxide superconductors

YBa2Cu3O7, with a critical temperature of 92 K, the bismuth-strontium-calcium-barium oxide superconductors Bi2Sr2Ca2Cu3O10

and Bi2Sr2CaCu2O8, with a

critical temperature of 110 K and 85 K respectively and the thallium-barium-calcium oxide

superconductors Tl2Ba2Ca2Cu3O10,

with a critical temperature of 125 K. All these materials have as common

feature a crystal structure that includes layers of copper-oxygen planes,

through which the superconducting current flows.

In the BCS quantum-mechanical theory of conventional

superconductors, the electron flux consists of bound pairs of electrons. The

pairing is caused by an attractive force between electrons. The electrons are bound in Cooper pairs by

an electron-phonon interaction, i.e. by phonon-mediated pairing. The electron's

wave function that describes the pair is spherical, indicating that the chance

of finding one carrier in a Cooper pair given the position of the other falls

off at the same exponential rate in all directions in space. This pairing is said to

have s-wave symmetry.

The HTS superconductors display many of the well-known

properties of conventional superconductors, such as Josephson tunneling, vortex

structure, type II behavior and Meissner effect. However, they also have properties that are unusual for BCS-like

materials. Some of these are their high critical temperature, their linear dc resistivity

in the normal state and their extremely small coherence length, which is

comparable to the grain boundary thickness and therefore makes the weak-link

behavior a real problem for transport properties. In addition,

HTS are characterized by a large spatial anisotropy, which is due to their

layered crystal structure. These layers are composed of Cu-O planes, separated

from each other by planes of other oxides and rare earths. It is

believed that superconductivity and charge transport are mostly confined in the

Cu-O planes, called the ab planes, perpendicular to the c axis. This structural

anisotropy translates into anisotropy of most physical properties.

While it is admitted that there is some electron pairing

mechanism involved in high temperature superconductivity, the nature of the

pairing mechanism is not yet understood. It is considered that the pairing

interaction may not be phonon-mediated and may not be the same for all HTS

superconductors. Lattice vibrations alone are not strong enough to maintain electron pairing at elevated temperatures. Pairing mechanisms of magnetic origin have been proposed, mainly

to justify the high critical temperatures of HTS: the magnetic exchange energies

are about four times the phonon energies. In this case, the electron pairing

would have a wave function with d-wave symmetry. The d-state

appears as a four lobes lying in a plane, like a four-leaf clover. One of the

most dominant theories that contains d-wave symmetry is the spin wave model.

According to this theory, the carrier leaves a magnetic disturbance (a spin

wave) in its wake. This wake pulls a second carrier, so that the two forms a

Cooper pair. The spin waves are short-lived, so they are often called spin

fluctuations. However, some measurements are

in apparent contradiction with this picture. For instance, results of Josephson

tunneling experiments are an argument for the paired electrons being in a

spin-singlet s-state. It was pointed out that Josephson tunneling should not be

possible between paired electrons in two different superconductors unless they

have the same symmetry. The Josephson tunneling experiment between

yttrium-barium-copper-oxide superconductors and a Pb/Sn (an ordinary s-wave

superconductor) point contact, would be in favor of paired electrons in a s-state. Also, the temperature-dependent penetration-depth for HTS gives

weight to the argument that these materials are s-wave. Phonon mediated pairing

would be

consistent with the experimentally observed s-state pairing.

For the electron pairing mechanism,

other quasiparticles such as antiferromagnetic magnons or excitons have also been

proposed as pairing intermediates. Alternatively, other mixed mechanisms have

been considered, like a phonon-mediated mechanism with some sort of a booster to

increase the critical temperature of the superconductor.

The MgB2

superconductor, discovered in 2001 by a team

of Japanese researchers, does not belong to the family of cuprates. This superconductor,

with a critical

temperature of 39 K, is not a copper oxide: it is a much simpler compound that seems to represent a whole new

superconductor family, more than being simply a Low Temperature Superconductor (LTS) with an unusually

high critical temperature. The large isotope effect found in this superconductor

confirms the key role of electron-phonon coupling. However, the electronic

structure in MgB2 is such that there are two types of electrons at

the Fermi level, one of them being much more strongly superconducting than the

other. This is in contrast with the theory of phonon mediated superconductivity,

which assumes that all the electrons behave in the same manner.

It is certainly true that the HTS field

is still young and it evolves rapidly. It is also true that it took

45 years after the discovery of superconductivity in solid mercury at 4.2 K -by Kamerlingh Onnes

in 1911- to arrive at a solid understanding of conventional

superconductors through the microscopic BCS theory. While some practical HTS

superconductors are now being made and some applications are appearing, it is

felt that it may still be a long time before the physics of HTS is fully understood and explained in one -or more- theories

enjoying consensus among

theoretical physicists. Progress in the field has been, up to now, mainly driven

by experimental work. Finding a theory would probably help researchers to

address some of the problems encountered when working with this new generation

of superconductors.

Applications

HTS materials have already been used to demonstrate a variety of applications.

In the field of large-scale applications, where high currents and long lengths

are required, power transmission cables, fault current limiters, transformers, motors

and generators have been made using both 1st and 2nd generation HTS. For small-scale

applications, where more specialized properties of HTS tend to be used,

examples are detection systems and analog and digital processing.

Different type of materials are commercially available today:

-

Bi-2223 (Bi2Sr2Ca2Cu2Ox)

multi-filamentary tape (1st generation superconductor). This material is

available on the market in long (about 1 km) lengths. The tape, which is typically

about 4 mm wide and 0.2 mm thick, is produced with the Powder In Tube (PIT) process. It has a silver alloy matrix,

which is reinforced either by alloying or by attachment to a metallic

substrate to improve its strength tolerance.

-

Bi-2212 (Bi2Sr2CaCu2Ox) multi-filamentary wire and tape (1st generation superconductor). It

is also available in long lengths. Having a high critical field, it is

particulary suited for high current or high field applications at

temperatures below 20 K, such as inserts in high field magnets.

-

Y-123 (YBa2Cu3O7-x)

coated conductors (2nd generation superconductor), where a bi-axially

textured superconductor is coated on a flexible ribbon. This material is in

these days becoming available on the market in lengths of about 100 meters. It is expected to

replace the Bi-2223 because of its higher critical temperature and field and

the lower cost of raw materials.

-

Bulk melt-textured Y-123 and melt-cast processed Bi-2212

materials for novel applications such as magnetic bearings, magnetic

shields, flywheels and current limiters.

-

MgB2 in the form of bulk, tape and wire. It

can be produced either with in-situ (reaction between Mg and B) or ex-situ

(sintering of MgB2 powders) processes. It has a relatively low

critical temperature (39 K), but a high potential in view of the low cost of

raw materials and manufacturing processes. It is becoming available in long

lengths in the form of wire and tape.

In the LHC we take advantage of the unique properties of the

HTS material to reduce considerably the heat in-leak via the current leads. Stacks of Bi-2223 tape

in a silver-gold matrix are used to feed more than 3 MA of

current to the superconducting magnets operating at liquid helium temperature. The LHC current leads, which represent

the first application of HTS material for accelerator technology, provide a

unique opportunity to demonstrate the value of incorporating HTS materials into a

large scale system

HTS materials for LHC current

leads

|

As part of an intensive R&D program which started in early 1995 and ended in

2002, a full range of HTS materials were studied and tested at CERN. The

scope of this work was to

verify their current capability at temperatures of up to 77 K, their

suitability for reproducible low resistance and high current joints, their

behavior in case of resistive transition and their thermal performance.

These materials, tested either in the form of samples or integrated in prototype

current leads, were: Bi-2223 tape with various percentage of Au in the Ag

matrix, DIP coated Bi-2212, Melt Cast Processed Bi-2212, Accordion Folding

Method Bi-2223, Melt Textured Y-123, Ceramo Crystal Growth Y-123 and Laser

Floating Zone Bi-2212.

In view of its good thermal and electrical performance and established

quality control procedures associated with industrial scale production, the

Bi-2223 tape was identified as being the most suitable material for

application to the LHC HTS current leads.

Bi-2223 tape and Bi-2223 stacks

Thirty-one kilometers of Bi-2223 tape were purchased from two manufactures (AMSC

and EAS). The tape was specified to have superconducting filaments-

(Bi,Pb)2Sr2Ca2Cu3OX,

X »

10- embedded

in a silver alloy matrix doped with gold. The percentage of gold in the

matrix is in the range from 4 to 5.3 weight percentage.

The tape, 4 mm wide and 0.2 mm thick, was delivered in spools having a

minimum length of 100 metres. The measured average critical current of the

spools, at 77 K and in self-field, is about 100 A.

The Bi-2223 tape is

integrated in the current leads in form of stacks. A number of five to nine

tapes are vacuum soldered together to form a comparatively rugged conductor

transporting, at 77 K and in self-field, a current between 350 A and 600 A. This

activity of vacuum soldering of the tapes into stacks is performed at CERN:

the tape is inspected, cut to the required length, assembled into

appropriate moulds and vacuum soldered in the CERN vacuum soldering

facilities. About 10000 HTS stacks are being manufactured at CERN for

integration in the LHC current leads. As part of the quality control

program, all stacks are characterized in liquid nitrogen and in self-field. The n-exponent

value of the stacks, calculated

as the

slope of the logarithmic plot of the voltage versus current in the range

from 0.1

mV/cm

to 2

mV/cm,

is about 20. For all stacks, the critical current

is measured for electric fields of

0.1 mV/cm,

1 mV/cm

and 2.5 mV/cm.

For full

traceability, the spool and the stack characteristics and their

characterization curves

are stored in a database, together with the information related to

the current lead and to the LHC magnet circuit powered by the leads.

Some stacks, representative of each different type integrated in the current

leads, underwent a full characterization at 77 K and 65 K in magnetic

fields, parallel and perpendicular to stacks, of up to 0.5 T.

Short samples of Bi-2223 tape underwent tests of irradiation by fast

neutrons both at room and liquid nitrogen temperatures. It was found that

integrated doses of up to 5.10-15 cm-2 ,

equivalent to about 500 kGy, do not give rise to significant degradation of the

critical current of the tape.

To prevent "bubbling" of the stacks, which will be exposed during the LHC

operation to liquid helium and cold helium gas, a coating procedure has been

proposed and validated by CERN. It consists in the vacuum impregnation of

the HTS stacks with a thin layer of the polymer poly-para-xylene (ParyleneÒ).

The vacuum impregnation takes place at room temperature on the stacks

already assembled on the supporting structure that is part of the current

lead assembly.

|

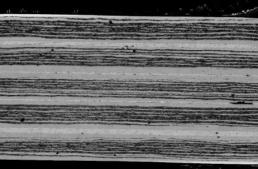

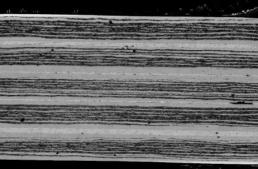

Stack of HTS Bi-2223 tapes

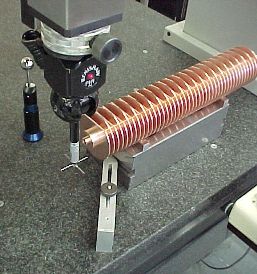

Characterization in of Bi-2223 stacks at 77 K

Critical current of a Bi-2223 stack meaured at 77 K and in self-field

Average critical current of different spools (41 in total) of Bi-2223 tape

Micrograph of a Bi-2223 stack

Set-up for characterization of Bi-2223 stacks

|

LHC HTS Current leads

|

The LHC will require the transfer of more than 3 MA of current for the

powering of the superconducting magnets operating at superfluid helium

temperature. About 26 % of this current is transported by leads feeding the

main dipole and quadruple magnets (13000 A), 54 % by leads powering the

insertion magnets (3400 A-6800 A), 17 % by leads for the corrector

magnet circuits (600 A) and the remaining 5 % by leads for the dipole corrector

magnets (60 A-120 A). Prior to starting the design of the LHC leads, a study

was made to evaluate the exergetic costs of different cooling methods

available within the already well-defined infrastructure of the LHC machine,

and the potential saving in liquefaction power induced by the use of HTS

material. The most convenient

solution, finally adopted for all the LHC HTS current leads, consists in

cooling the resistive part of the lead with 20 K/1.3 bar helium gas,

recovered from the LHC beam screen cooling line, while the HTS element

operates in self-cooling conditions between an intermediate temperature (THTS) and the 4.5 K

liquid helium bath. The estimated saving in total cooling power with

respect to conventional self-cooled current leads, which conduct into the

helium bath about 1.1 W/kA, corresponds to 30 % while the heat

load into the liquid helium is reduced by a factor greater than 10.

These values were confirmed by several measurements performed at CERN on

prototype leads. It was decided to integrate HTS material in all the current

leads transporting currents ranging from 600 A to 13000 A.

The LHC HTS current leads operate in a temperature range between room

temperature and the saturated liquid helium bath. They consist of a

resistive section, convection cooled by helium gas available in the LHC

machine at a nominal temperature of about 20 K, and a superconducting

section, self-cooled by the vapour generated by the lead itself at 4.5 K.

The two circuits are hydraulically separated. The warm end of the

superconducting section, THTS, is maintained at 70 K in stand-by

operation and at 50 K in operation with current. Integrated within the

current lead body is the instrumentation required for its operation and protection: a platinum sensor, at the top of the HTS unit,

used for the control of the 20 K helium mass flow rate, and the voltage taps

which are provided for independent protection of the resistive (100 mV

threshold) and HTS part (5 mV threshold). Additional voltage taps are made

available for the protection of the magnet circuits.

The detailed design of the leads was made at CERN, where the prototype units

were also tested in cryogenic conditions. The leads are grouped in three

different series, designed for operating respectively at 13000 A,

6000 A and 600 A.

A pre-series of 140 units was manufactured and

assembled at CERN. The complete series of leads is being manufactured in CECOM, Rome, for the 13000 A leads and in the Russian laboratory of BINP,

Novosibirsk, for the 6000 A and 600 A current leads, on the basis of CERN

"build-to-print" designs. All HTS current leads are measured at maximum

current prior to installation in the LHC machine: the laboratory of ENEA,

Frascati, measures the series of 13000 A and 6000 A HTS current leads, while

the University of Southampton measures the series of 600 A HTS current

leads.

The 13000 A and 6000 A current leads are manufactured as single

units, while the 600 A current leads are assembled in a group of four on a

common insulating flange. The table below summarizes the typical performance

of the three different type of leads when operating at maximum current, as already repeatedly measured on hundred

of units.

| Current lead type |

Current (A) |

Mass flow rate of 20 K He gas (g/s) |

Heat load at 4.5 K (W) |

| 13000 A |

13000 |

≤0.63 |

<1.5 |

| 6000 A |

6000 |

≤0.3 |

<0.7 |

| 600 A |

600 |

≤0.034 |

<0.09 |

|

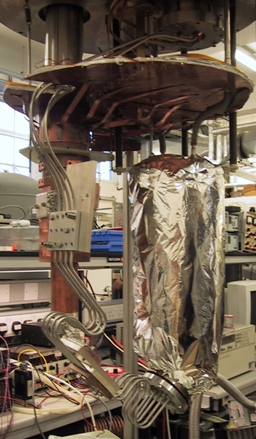

The 13000A HTS unit

Test at CERN of 13000 A prototype lead. Measurements performed during a 4

hours run.

13000 A Heat exchanger |

LHC Resistive leads

|

The powering of

the LHC close orbit correctors will be made via 1504 current leads rated for a

maximum current of 60 A. Additional 520 current leads are needed for the

powering of the corrector magnets operating at currents of up to 120 A. At CERN, two different designs

were developed for these leads:

· a

conduction-cooled design, for all the 60 A leads and for part -324 in total- of the

120 A leads;

· a

gas-cooled design for the remaining 120 A current leads.

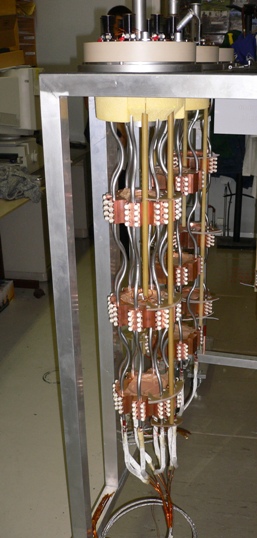

Conduction-cooled current leads

The

conduction-cooled current leads are integrated in the main vacuum insulation

of the LHC Short Straight Section (SSS) cryostats. They transport the

current from room temperature to the 1.9 K liquid helium bath. In view of

their important number and of the strong space constraints imposed by the

cryostat configuration, they are assembled in a group of four on a common

stainless steel flange. They are pre-shaped as requested by the integration

requirements, which require that these leads are the last components to be

integrated into the already densely packed LHC cryostats.

An hybrid

conductor, electrical insulated via a multilayer Kapton® tube, is first

inserted in a thin stainless steel tube and then pre-shaped with a tooling,

specially developed at CERN. The four tubes are finally welded to the warm

and cold stainless steel flanges. The hybrid conductor is a red brass rod that

is copper plated along the entire length with two different copper

thickness (thinner in the lower part). This hybrid conductor was chosen in order to minimize the heat

load into the helium bath while assuring good stability in case of thermal

run-away. The conductors of each assembly are thermalized against two heat

sinks that are fixed to two cryogenic lines carrying gas

at 50 K-75 K and at 5 K-20 K respectively. The heat sinking at intermediate

temperatures is made in order to minimize the heat losses into the liquid

helium bath.

The design of

these leads is extremely compact. It has the advantage, when compared to

conventional self-cooled leads, of not requiring warm valves and pipes for

the control and recovery of the helium flow. It avoids the use of cold

vacuum-tight ceramic feedthroughs. In addition, thanks to the material choice and to the good

design of the heat sinks, the leads have good thermal performance. The calculated

losses into the helium bath of the a 60 A current leads are < 90 mW

at 15 A, which is the average current estimated for these corrector

magnets, and 170 mW at maximum current. For comparison, a conventional

conduction-cooled current lead operating at 60 A would conduct about 2.5 W into the bath.

The predicted thermal and electrical performance of the 60 A current leads have been

confirmed by precise measurements performed on series components integrated in a

ad-hoc cryostat built in the

University of Southampton.

The series

production on the 60 A and 120 A conduction-cooled current leads is being

manufactured on the basis of a CERN "build-to-print" design respectively in

Mark&Wedell, Copenhagen, and in CECOM, Rome.

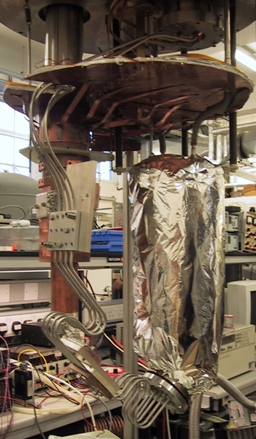

Gas-cooled current leads

The

gas-cooled current leads are integrated in cryostats, located in the

insertion regions of the LHC machine, which house also the HTS current

leads. They transport the current from room temperature to the 4.5 K liquid

helium bath. The design is very compact. Depending on the requirements of

the powering, the leads are assembled in groups of four or eight on a common

supporting flange. The novelty of this design with respect to conventional

self-cooled current leads consists in extracting the heat from the leads of

the same assembly via common heat exchangers, cooled by the gas produced by

the thermal conduction of the leads themselves at 4.5 K. This solution has

two important advantages: the reduction in the number of valves

needed for the cooling of the leads from one per lead to one per lead

assembly, with significant economical savings in particular in view of the

important number of leads, and the compactness of the design, which is made

possible also by the simplification of the cooling scheme. The thermal

performance of these leads is comparable to the one of conventional

self-cooled current leads optimized for the same current rating.

|

60 A Current Lead Assembly

60 A Current Lead Assembly in LHC cryostat

120 A current lead assembly in SSS cryostat

Cryogenic test, in ENEA, of 120 A

gas-cooled current lead

assembly (8 leads)

120 A gas-cooled current lead assembly |

Other activities

As part of the

laboratory activity, assembly work and different types of measurements are

performed within the AT-MEL-CF section. The latter include both series measurements on the current

leads that are carefully checked prior to integration in the LHC tunnel - leak tightness,

high voltage electrical

insulation and instrumentation tests - and measurements on different type of

materials to verify their thermal and electrical properties at cryogenic

temperatures. In particular, the following measurements are performed:

-

RRR

(Residual Resistivity Ratio) measurements;

-

Thermal

conductivity measurements in the range from 50 K to 4.2 K;

-

Critical

current measurements of HTS materials at liquid helium and liquid nitrogen

temperatures.

The

section is also in charge of the specification, procurement and supply of the

electrical equipment needed for the operation of the current leads in the LHC

tunnel. This is the equipment required for the powering and control of the

cartridge heaters integrated at the top of the leads to avoid condensation in

stand-by conditions and includes more than a thousand of isolation

transformers, heaters and heater control units and kilometers of power and

instrumentation cables.

Contracts

|

While the conception, the optimization and the detailed design of the LHC leads was made at CERN, where prototypes of each type of current lead were built and tested, the series production of the components is being carried out in companies and external laboratories on the basis of the CERN

specifications and drawings. The electrical characterization

at cryogenic temperatures of the series of HTS leads is also made by external laboratories.

-

Manufacture and supply of 13000 A HTS Current leads. CERN

Technical Specification document IT-3168/AT/LHC: Manufacture and Supply of

13000 A HTS Current Leads, September 2003, Amalia Ballarino. Contractor: CECOM, Frascati, Italy.

-

Manufacture and supply of 6000 A HTS Current Leads. CERN

Technical Specification document: Manufacture and Supply of 6000 A HTS

Current Leads, June 2004, Amalia Ballarino. Collaboration

Agreement with BINP, Novosibirsk, Russia.

-

Manufacture and supply of 600 A HTS Current Leads. CERN

Technical Specification document: Manufacture and Supply of Assemblies of

600 A HTS Current Leads, June 2004, Amalia Ballarino. Collaboration Agreement with BINP,

Novosibirsk, Russia.

-

Manufacture and Supply of 60 A conduction-cooled Current Leads.

CERN Technical Specification document IT-2901/AT/LHC: Manufacture and Supply

of Assemblies of 60 A resistive Current Leads for the LHC Dipole Corrector

Magnets, June 2002, Amalia Ballarino. Contractor: Mark&Wedell,

Copenhagen, Denmark.

-

Manufacture and supply of 120 A conduction-cooled Current Leads.

CERN Technical Specification document DO-21889/AT/LHC: Manufacture and

Supply of Assemblies of 120 A Current Leads for the LHC Dipole Corrector

Magnets, May 2004, Amalia Ballarino. Contractor: CECOM, Frascati,

Italy.

-

Manufacture and supply of Bi-2223 tape. CERN Technical

Specification document IT-3143/AT/LHC, Manufacture and Supply of BSCCO 2223

Au-Au Tape, March 2003, Amalia Ballarino. Contractors: ASC, USA, and EAS, Hanau,

Germany.

-

Cryogenic Test of 13000 A and 6000 A HTS Current Leads.

CERN Technical Specification document IT-3303/AT/LHC: Cryogenic Testing of

HTS Current Leads, March 2004, Amalia Ballarino. Contractor: ENEA, Frascati,

Italy.

-

Cryogenic Test of 600 A HTS Current Leads. CERN Technical

Specification document IT-3303/AT/LHC: Cryogenic Testing of HTS Current

Leads, March 2004, Amalia Ballarino. Contractor: University of Southampton, UK.

-

Cryogenic Test of 60 A and 120 A conduction-cooled current leads.

Collaboration Agreement No. CA 1298831, University of Southampton.

-

Electrical characterization of HTS Bi-2223 stacks.

Collaboration Agreement No. CA 1298846, CESI, Milano, Italy.

-

Design and production of prototype assembly of 50 A conduction-cooled current leads,

License and Consultancy Agreement with Desy, Hamburg, Germany.

-

Irradiation measurements on HTS materials,

Collaboration agreement with the Russian Research Centre "Kurchatov"

Institute (terminated).

In addition to the above listed contracts and collaboration

agreements, some activities related to the current leads project are performed

in-house. These activities are:

-

Production of more than 10000 Bi-2223 stacks, in collaboration with the CERN specialists of vacuum soldering and vacuum brazing technologies.

-

Manufacture and assembly of 120 A gas-cooled current leads, in collaboration with the CERN Main Workshop.

|

Test in ENEA of 13000 A HTS current leads

Test in ENEA of 13000 A HTS current leads

CERN and BINP team in Novosibirsk

Test in Southampton of 60 A current leads

Test in Southampton of 600 A current leads |

Publications

List of main publications

First Test of Twisted-Pair HTS 1 kA Range Cables for Use in Superconducting Links, Proceedings of EUCAS 2011

First Electrical Characterization of Prototype 600 A HTS Twisted-Pair Cables at Different Temperatures, Proceedings of EUCAS 2011

Design of the HTS Current Leads for ITER, Proceedings of MT-22 (2011)

Alternative Design Concepts for Multi-Circuit HTS Link Systems, A. Ballarino, ASC 2010, IEEE Transactions on Applied Superconductivity, Vol. 21, No.3, June 2011

Design of an MgB2 Feeder System to Connect Groups of Superconducting Magnets to Remote Power Converters, A. Ballarino, EUCAS 2009, Journal of Physics: Conference Series 234 (2010) 032003

Scaling of Superconducting Switches for Extraction of Magnetic Energy, A. Ballarino and T. Taylor, IEEE Transactions on Applied Superconductivity, Vol. 20, No.3, June 2010

Conceptual Design of the LHC Interaction Region Upgrade - Phase I,

The LHC upgrade team, LHC Project Report 1163, CERN,

November 2008

Power Switches utilizing Superconducting Material for Accelerator Magnets,

S. A. March, A. Ballarino,

Y. Yang, ASC 2008, Chicago

Commissioning of the LHC Current Leads,

A. Ballarino, S. A. March, K. H. Meb,

EPAC 2008, Genova

Performance of

the Superconducting Corrector Magnet Circuits during the Commissioning of

the LHC, The LHC

commissioning team, EPAC 2008, Genova

Large-Capacity

Current Leads, A. Ballarino, ISS 2007, Tsukuba

Extending the

use of HTS to Feeders in Superconducting Magnet Systems, A.

Ballarino,

K. H. Meb, T. Taylor, MT-20 2007, Philadelphia

Toward the Design of Power Switches

utilizing HTS Material, S. A. March, A. Ballarino, C. Beduz,

K. H. Meb, Y.Yang, EUCAS 2007, Brussels

Extending the

Application of HTS in Particle Accelerators, A. Ballarino,

K. H. Meb, T. Taylor, EUCAS 2007, Brussels

Quench

Characteristics of Ag/AuBi2223 HTS-stainless steel stack used for the Hybrid

Current Leads of the Large Hadron Collider, M. K. Al-Mosawi,

S. Avgeros, C. Beduz, Y. Yang and A. Ballarino, EUCAS 2007, Brussels

HTS Current Leads:

Performance Overview in Different Operating Modes, A. Ballarino, ASC 2006, IEEE Transactions on Applied Superconductivity, Vol.17, No. 2, June 2007

The Commissioning of the LHC Technical Systems, The LHC Hardware Commissioning Team, Proceedings of PAC 2007

Large Scale

Assembly and Characterization of Bi-2223 HTS Conductors, A.

Ballarino, L. Martini, S. Mathot, T. Taylor and R. Brambilla, Proceedings of ASC

2006, August 2006, Seattle

Full Cryogenic Test

of 600 A HTS Hybrid Current Leads for the LHC, M.K. Al-Mosawi,

S.A. March, C. Beduz, A. Ballarino and Y. Yang, Proceedings of ASC 2006, August

2006, Seattle

Cryogenic Test of High Temperature Superconducting Current Leads at ENEA, Advances in Cryogenic Engineering: Transactions of the Cryogenic Engineering Conference, Vol. 51, 2006

DC and AC

Electrical Characterization of Stacks of HTS Tapes, S. Ginocchio,

A. Ballarino, E. Perini, S. Zanella, Proceedings of ASC 2006, August 2006,

Seattle

HTS in the LHC &

in the LHC Upgrades, A. Ballarino, WAMDO Workshop, CERN, April

2006

Conduction-cooled 60 A resistive current

leads for the LHC dipole correctors, A. Ballarino, LHC Project Report

691, March 2004

13000 A HTS Current

Leads for the LHC Accelerator: from Conceptual Design to Prototype Validation,

A.Ballarino, S.Mathot, D.Milani, Proceedings of EUCAS 2003, September 2003,

Sorrento, Italy

Effect of fast neutron

irradiation on transport properties of HTS materials, T.Taylor,

A.Ballarino, A. Ryazanov et al, Proceedings of EUCAS 2003, September 2003,

Sorrento, Italy

First Results and Status of the LHC String 2, The String 2 Team, Proceedings of EPAC 2002

HTS

Current Leads for the LHC Magnet Powering System, A.Ballarino, Physica C

372-376 (2002) 1413-1418, Invited Paper at the EUCAS 2001 Conference, August

2001, Lyngby, Denmark

Current Leads for

the LHC Magnet System, A.Ballarino, Invited Paper at the 17th

International Conference on Magnet Technology, 24-28 September 2001, Geneva,

Switzerland

Application of High Temperature Superconductors to Accelerators,

A.Ballarino, Invited Paper at the Seventh European Particle Accelerator

Conference, 26-30 June 2000, Vienna, Austria

High Temperature

Superconducting Current Leads for the Large Hadron Collider, A.Ballarino,

Presented at 4th European Conference on Applied Superconductivity, Sitges,

Spain, September 1999, LHC Project Report 337

120 A

Current Leads for the DFBs, A.Ballarino, Engineering Specification, LHC

Project Document No. LHC-DFL-ES-0002,January 2005

LHC HTS Current

Leads, A.Ballarino, Functional Specification, LHC Project Document No.

LHC-DFL-ES-0001,July 2003

IT-2901/AT/LHC,

A.Ballarino, Technical Specification for the Manufacture and Supply of

Assemblies of 60 A Resistive Current Leads for the LHC Dipole Corrector Magnets,

LHC Project Document No. LHC-DFLD-CI-0001, June 2002

IT-3143/AT/LHC,

A.Ballarino, Technical Specification for the Manufacture and Supply of HTS BSCCO

2223 Ag-Au Tape, LHC Project Document No. LHC-DFLHT-CI-0001, March 2003

IT-3168/AT/LHC,

A.Ballarino, Technical Specification for the Manufacture and Supply of 13000 A

HTS Current Leads, LHC Project Document No. LHC-DFLA-CI-0001, September 2003

IT-3303/AT/LHC,

A.Ballarino, Technical Specification for the Cryogenic Testing of HTS Current

Leads, LHC Project Document No. LHC-DFL-CI-0005, March 2004

IT-600A,

A.Ballarino, Technical Specification for the Manufacture and Supply of

assemblies of 600 A HTS Current Leads, LHC Project Document No.

LHC-DFLB-CI-0001, June 2004

IT-6000A, A.Ballarino,

Technical Specification for the Manufacture and Supply of 6000 A HTS Current

Leads, LHC Project Document No. LHC-DFLC-CI-0002, June 2004

DO-21889,

A.Ballarino, Technical Specification for the Manufacture and Supply of

Assemblies of 120 A Current Leads for the LHC Dipole Corrector Magnets, LHC

Project Document No. LHC-DFL-CI-0001, May 2004